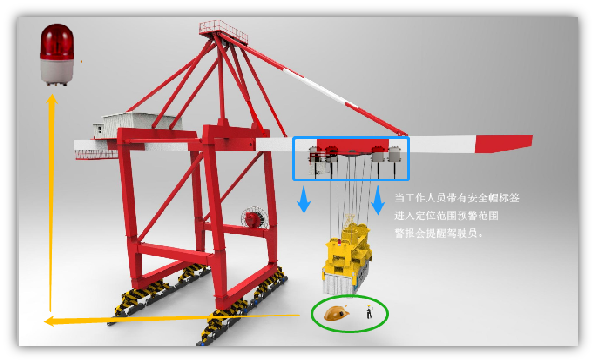

Worker Positioning and Protection (WPPS)

1. Feature introduction

Based on multi perspective visual recognition and perception technology, the WPPS provide real-time positioning for workers under the QC.

2. Technical indicators

(1)The overall positioning accuracy for the personnel under the QC is less than 30 cm, and the refresh rate is > 4 Hz

(2)Three-dimensional electronic fence shall be built around the spreader and container, with an accuracy of 30 cm

(3)The Recognize and detect rate for personnel under the container is more than 99%

(4)There is no omission of alarm for personel danger, and the system will not affect the shore crane operation

3. System features

(1) When the container operation is carried out on the quay crane, the system uses a laser scanner to automatically detect the hull contour information under the quay crane girder in real time

(2) By controlling the movement of the trolley and the lifting operation of the spreader, the intelligent deceleration and anti-collision protection of the spreader in the direction of the trolley and the lifting direction are realized, so as to avoid the collision accident between the spreader and the spreader lifting the container and the stacked container on the ship or the bilge and the side of the ship

(3)Through the scanning of two trolley directions, the laser scans the contour of the double 20-foot container to realize the collision prevention of the double container operation

(4)Scan the contour information of adjacent shells by scanning the direction scanning laser of the , control the movement of the trolley, and realize the anti-collision protection of adjacent shells

(6)Control the movement of the crane according to the data of the hull and container area scanned by the laser, realize the anti-collision protection in the direction of the crane, and avoid the collision accident between the spreader and the container under the spreader and the stacked container or bilge and the side of the ship

4. System benefits

(1)If someone is near a moving container under QC, an alarm will be triggered so as to standardize the operation process under the QC, and prevent personal injury accidents caused by containers or twist-locks

(2)Adopt industrial-grade, suitable for port machinery and seaside environment laser equipment, special brackets and protection devices to ensure the stable operation of the sensor

(3)The system increases the adaptability to the weather and environment (waterproof, dustproof, high and low temperature resistance, antistatic, seismic resistance, anti-electromagnetic interference)

(4)Intelligent processing of laser point cloud, automatic correction, fast contour acquisition, unique anti-collision strategy

(5)Standard industrial interface protocols for easy communication with other systems (PLC, ECS, RCMS, etc.)