Intelligent Twist-lock Handling Robot V2.0

1. Feature introduction

Integrating 3D laser and vision technologies to achieve precise positioning and recognition of containers and twist-locks, controlling precision robotic arms to achieve automatic disassembly, braiding reset, storage and transportation functions of twist-locks.

2. Technical indicators

(1)with a disassembly process of less than 30 seconds

(2)twist-lock inventory of 200 units

(3)15 minutes for single quick charge, keep operating up to 6 hours

(4)Elephant L inventory >300 units, Elephant T inventory > 64+NV (64) units

(5)Assemble and disassemble 40 feet /45 feet/twin 20 feet container twist-lock

3. System features

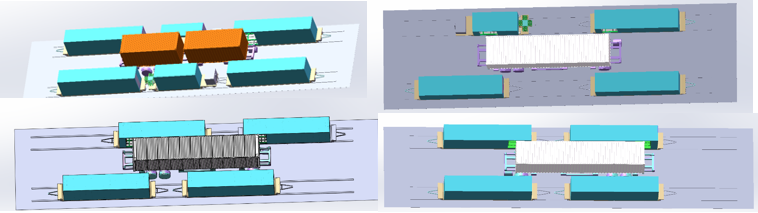

(1)Mobile Intelligent Twist-lock Robot support Elephant T mode and Elephant L model

(2)Combined with dedicated ECS software unmanned disassembly and assembly operations can be achieved.

(3)The system supports multiple work routes and multiple vessels for simultaneous operation, providing fixed and mobile deployment solutions to meet different operational process requirements.

(4)The system can exchange information with the TOS

(5)Each unit device can be movable and combined freely

(6)Modular design, adapt to fast maintenance, and provide remote system services

(7)Fully enclosed, all-weather, fully automatic operation

(8)Using 5G and UWB to communicate between devices and exchange information in the remote equipment room

(9)Adapts to all semi-automatic locks and all medium locks

4. System benifit

(1)It meets the task of removing and installing twist-locks for all operating routes and berths

(2)Any combination of Elephant T and L shapes can form a freely combination of 40 feet, 45 feet and double 20 feet operation channels

(3)To realize the exchanging of data and information with other automation systems of the terminal

(4)Supporting the all-weather continuous unmanned operation, to realize the visual digital twin synchronization in the terminal central control room